Blooming Test Monitor provides essential capabilities for optimizing testing processes and product quality. Its core advantages deliver tangible improvements, making it a strategic investment for development teams.

Precision Measurement for Quality Enhancement

Gain critical insights into material behavior and defect detection with unparalleled accuracy. Advanced algorithms identify subtle variations and early signs of failure, enabling proactive quality control and significantly reducing the risk of subpar products reaching market.

Seamless Integration into Existing Systems

Minimize disruption and accelerate ROI through its flexible architecture. The monitor effortlessly interfaces with industry-standard testing equipment and software platforms, requiring minimal reconfiguration and protecting existing investments while enhancing overall workflow cohesion.

Increased Testing Throughput and Speed

Reduce cycle times and boost productivity dramatically. Real-time, non-intrusive monitoring eliminates manual intervention and waiting periods, allowing for continuous operation and the execution of more tests within the same timeframe, directly impacting project timelines.

Intuitive User Experience and Streamlined Operations

Empower staff with straightforward tools requiring minimal training. The clear interface displays relevant data immediately, simplifying decision-making and reducing operator errors, which lowers operational costs and ensures consistent testing standards are applied universally.

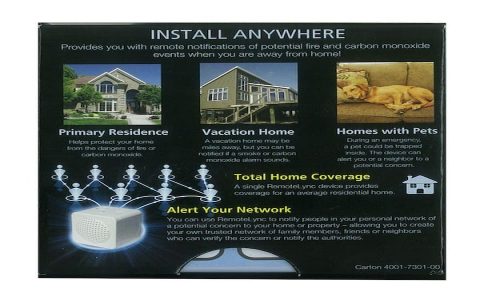

Predictive Maintenance and Cost Avoidance

Protect valuable assets and optimize maintenance planning. Proactive monitoring of the bloom's condition and associated equipment enables data-driven predictive maintenance, preventing unexpected downtime, costly repairs, and production stoppages, ensuring continuous operation.

Core Reasons to Invest:

- Superior Quality Assurance through defect identification and behavior analysis.

- Operational Efficiency via seamless integration and accelerated testing.

- Reduced Downtime enabled by predictive equipment maintenance insights.

- Cost Savings by minimizing waste, rework, and unplanned repairs.

- Enhanced Scalability providing adaptable solutions for future testing demands.