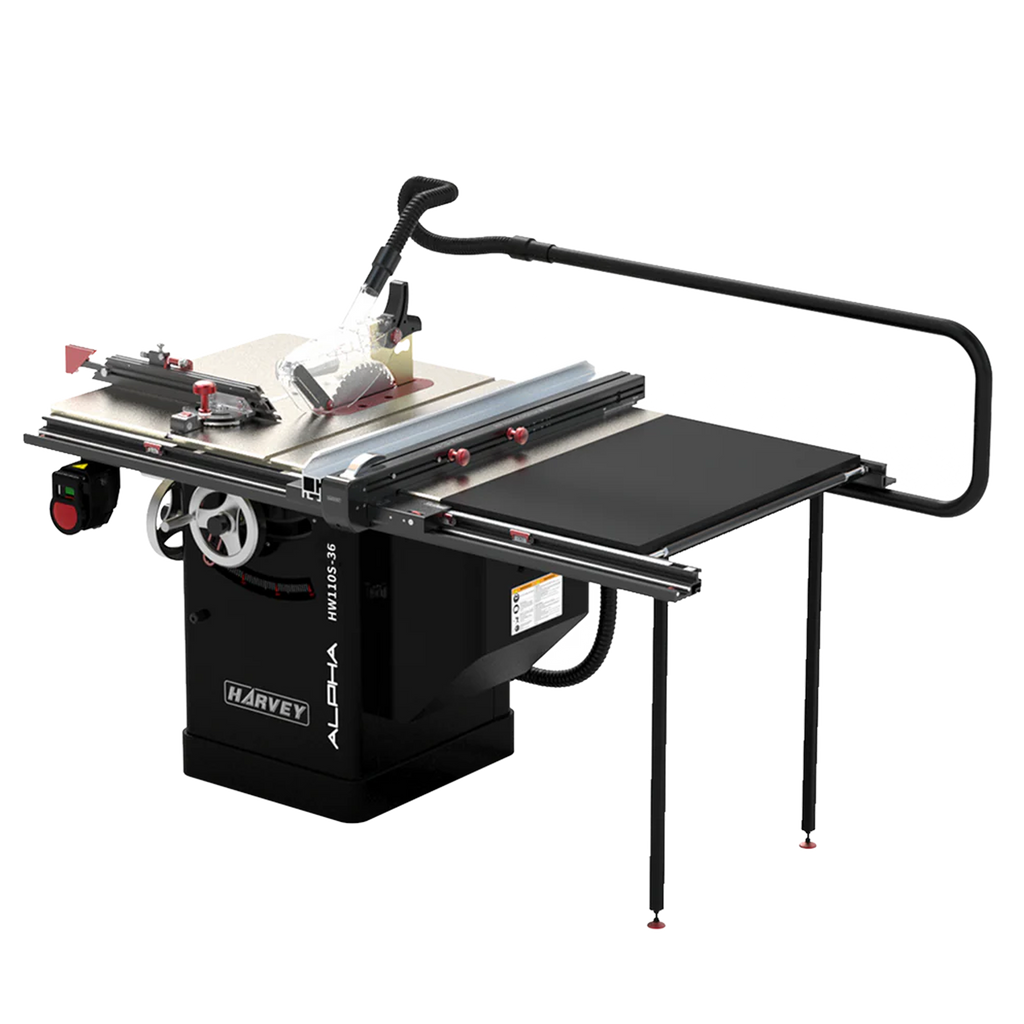

Proper setup is critical for achieving precision cuts and safe operation with your Harvey table saw. Follow these essential steps:

Critical Initial Alignment

Blade & Miter Slot Parallelism: Use a reliable dial indicator or combination square. Ensure the blade is parallel to the miter slot within 0.003" (0.076mm) along the front and back. Adjust the trunnion or table mounts if necessary. This is foundational for accurate rip and cross-cuts.

Fence Calibration: Verify the fence is parallel to the miter slot (and thus the blade) throughout its travel. Misalignment causes binding and kickback. Adjust fence rails and locking mechanisms per the manual.

Essential Setup Components

- Arbor Runout Check: Mount a dial indicator on the table. Measure blade wobble near the arbor flange. Minimize runout to under 0.005" (0.127mm) by ensuring blades are clean and properly seated.

- Zero-Clearance Inserts: Install inserts specific to your blade width. This prevents thin stock from catching and dramatically improves cut quality.

- Splitter/Riving Knife Alignment: Position directly behind the blade, coplanar with it and aligned within 1/32" (0.8mm) of the blade plate. Crucial for preventing kickback.

Optimizing Blade & Cutting

Quality Blade: Use a sharp, high-quality blade appropriate for your material (e.g., ATB for cross-cutting, FTG for ripping). Check for damaged or bent teeth.

Height & Angle: Set blade height so gullets clear the material (~1/4" to 1/2"). Set bevel angle accurately using a digital gauge against the table surface for precise angle cuts.

Safety & Performance Checks

- Power & Dust: Ensure the saw is on a dedicated circuit if possible. Connect dust extraction directly to the saw port; verify strong suction at the blade guard.

- Safety Devices: Confirm smooth, tool-free adjustment of the blade guard and anti-kickback pawls. Test the emergency off switch.

- Test Run: Power on without load. Listen for unusual vibrations or bearing noise. Observe blade stability.

Routinely recheck alignment after moving the saw or heavy use. Consistent setup ensures peak performance and safety.