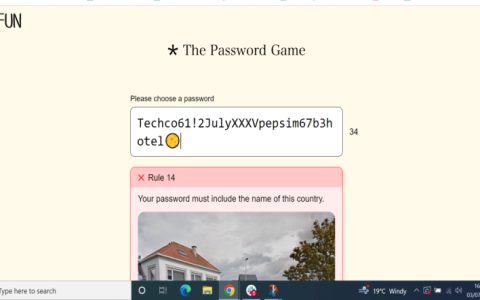

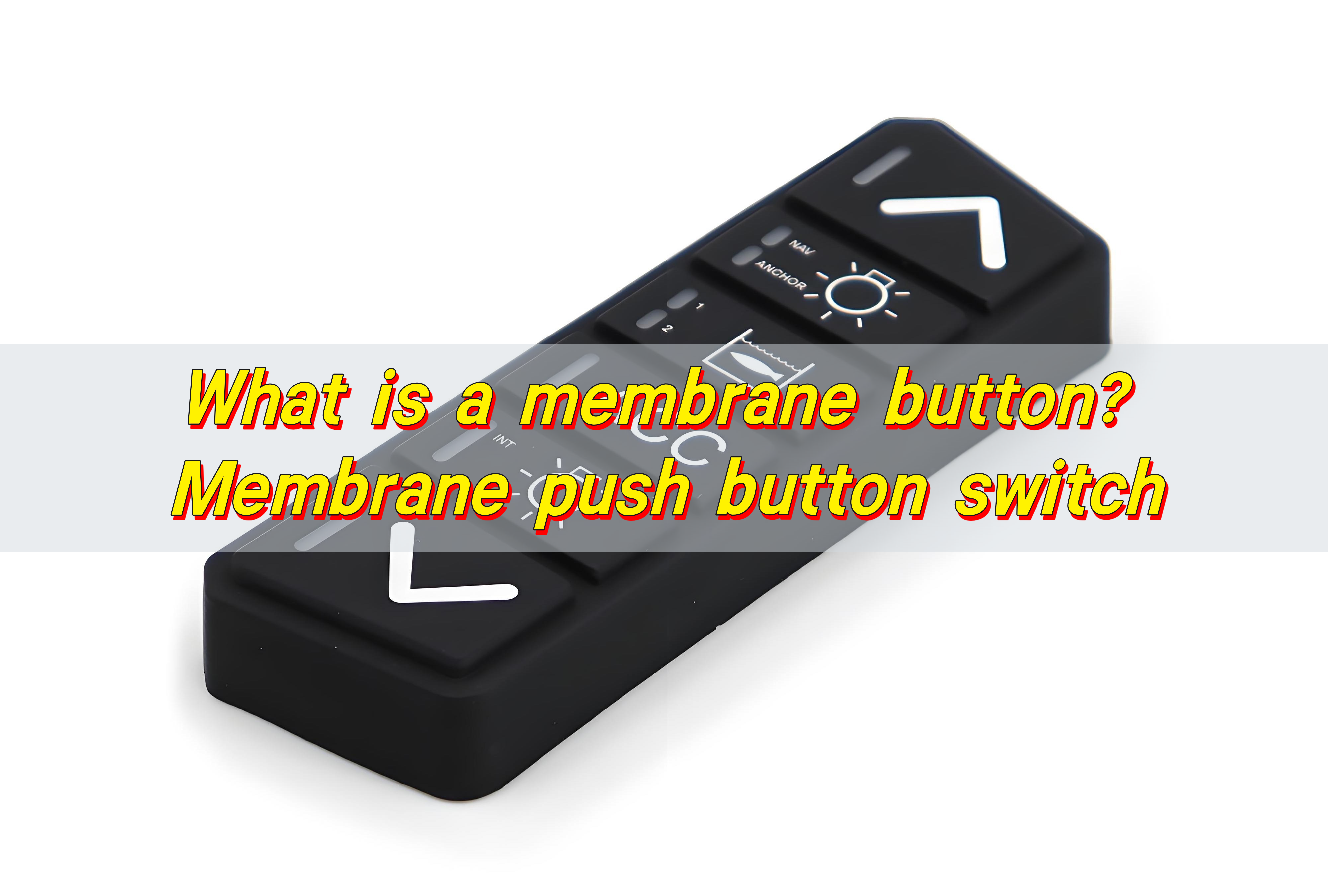

A membrane button, often part of a membrane switch assembly, is an electrical input component where user pressure on a flexible top surface makes or breaks an electrical circuit. Unlike traditional mechanical buttons with moving parts, membrane buttons rely on the deformation of thin, conductive layers.

Construction and Layers

A typical membrane button construction involves several laminated layers:

- Graphic Overlay: The outermost layer, usually made of polyester or polycarbonate. It carries printed graphics, symbols, or button labels and provides a protective, often wipeable, surface. It's frequently printed on the reverse side to protect the graphics from wear.

- Overlay Adhesive: A thin adhesive layer that bonds the graphic overlay to the top circuit layer.

- Top Circuit Layer: A flexible polyester film with conductive silver or carbon ink traces printed on its underside. This layer forms one half of the switch contact.

- Spacer Layer: An adhesive layer with cutouts in the button areas. This layer separates the top and bottom circuit layers, creating a precise air gap. The thickness of this layer can influence tactile feel.

- Bottom Circuit Layer: Another flexible polyester film with conductive traces printed on its top side. This forms the other half of the switch contact. In some designs, this can be a rigid PCB.

- Rear Adhesive: An adhesive layer used to mount the entire membrane switch assembly to an enclosure or a rigid backer panel.

Tactile Elements: To provide tactile feedback, metal domes (snap domes) or embossed polydomes (formed domes in the graphic overlay or a dedicated dome carrier layer) can be incorporated. These elements provide a distinct "click" sensation upon actuation.

Working Principle

When a user presses a designated button area on the graphic overlay:

- The pressure deforms the graphic overlay and the top circuit layer beneath it.

- The conductive trace on the underside of the top circuit layer is pushed through the cutout in the spacer layer.

- This action brings the conductive trace on the top circuit layer into contact with the corresponding conductive trace on the bottom circuit layer.

- The contact completes the electrical circuit, signaling a button press to the connected electronics.

When the pressure is released, the inherent elasticity of the layers (or the spring action of a tactile dome) causes the top circuit layer to return to its original position, breaking the electrical contact and opening the circuit.

Key Characteristics and Advantages

- Sealing: Easily sealed against dust, moisture, and chemicals (e.g., IP65, IP67 ratings), making them suitable for harsh environments.

- Low Profile: Their thin construction allows for sleek and compact product designs.

- Customization: Highly customizable in terms of graphics, colors, shapes, and backlighting (e.g., LED integration).

- Cost-Effectiveness: Generally economical, especially for interfaces with multiple buttons or complex layouts, due to printed circuit technology.

- Durability: Can achieve high actuation life cycles (millions of operations) depending on materials and design.

- Ease of Cleaning: The smooth, continuous surface of the graphic overlay is easy to clean and sanitize, beneficial for medical and food industry applications.

- Integration: Can integrate other components like LEDs, resistors, and even transparent conductive windows for displays.

Common Applications

Membrane buttons are widely utilized across various industries:

- Medical Devices: Control panels for patient monitoring systems, diagnostic equipment, and infusion pumps.

- Industrial Controls: Human-Machine Interfaces (HMIs) for machinery, process controllers, and instrumentation.

- Consumer Electronics: Remote controls, kitchen appliances (microwaves, ovens), fitness equipment.

- Automotive: Dashboard controls, steering wheel buttons, interior control panels.

- Point of Sale (POS) Systems: Keypads for cash registers and payment terminals.

- Telecommunications: Control panels for network equipment and test devices.

Considerations

- Tactile Feedback: Non-tactile versions offer no physical click, relying on visual or audible feedback. Tactile versions with domes improve this but may feel different from discrete mechanical switches.

- Repairability: Due to their laminated and sealed construction, repair is generally not feasible; faulty units are typically replaced.

- Actuation Travel: The travel distance is very short compared to many mechanical switches.